Massachusetts Home Inspections YOUR INVESTMENT IS MY CONCERN

Aluminum Branch Wiring

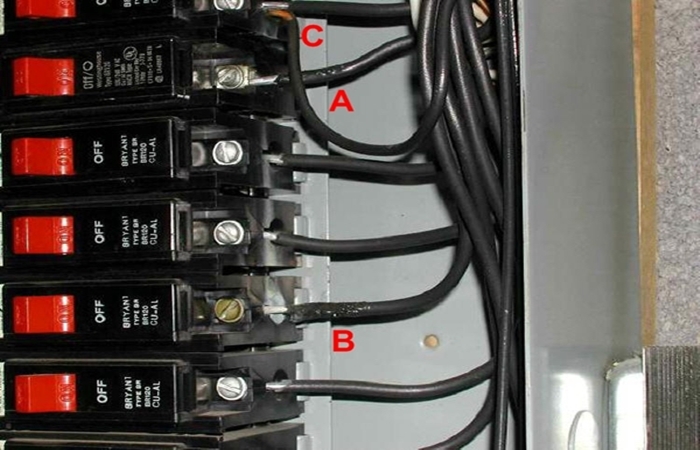

The image above provides a clear example of the issues commonly associated with aluminum branch wiring. Notice points A and B, where the insulation jackets are melted. I will explain the reasons behind this in the third paragraph. Additionally, point C highlights a hazardous issue — the mixing of copper and aluminum wiring on the same breaker. Aluminum branch wiring must never be combined with copper branch wiring, and breakers should not be double-tapped with two wires unless specifically designed for it. In cases where double-tapping is permitted, the breaker will include a designated clip to secure both wires properly. Aluminum branch wiring can be easily identified by its distinct silver-colored appearance. However, it’s important not to confuse it with tin-coated copper wiring, which may appear similar. The key difference is that aluminum branch wiring consists of a solid conductor, whereas tin-coated copper has different structural properties. Proper identification and handling of these materials are essential to ensure electrical safety.

In the 1970s, solid aluminum branch wiring gained popularity as a cost-effective alternative to copper and was commonly used in homes across the United States. However, it was eventually linked to numerous house fires, prompting many jurisdictions to prohibit its use in new installations. I strongly advise against using solid aluminum branch wiring for any new projects. If your home already contains aluminum wiring, there's no need to panic. When properly installed and maintained, aluminum wiring can be just as safe as copper. However, it is far less forgiving of improper installation, which increases the risk of electrical hazards. In the following sections, I will explain the specific risks associated with aluminum wiring and provide practical tips to ensure the safety of your home's electrical system.

The primary concern with aluminum branch wiring is a phenomenon known as "cold creep." As aluminum wiring heats up, it expands, and when it cools down, it contracts. Unlike copper, aluminum is prone to gradually loosening at connection points due to these repeated heating and cooling cycles.

To further complicate matters, aluminum oxidizes (or corrodes) when it comes into contact with certain metals. This oxidation increases the resistance at the connection, leading to excessive heat buildup. The heat accelerates further oxidation and corrosion, creating a dangerous cycle. Over time, this can cause the wire to become extremely hot, potentially melting the insulation jacket or damaging the fixture it is connected to — significantly increasing the risk of fire.

Since aluminum wiring is most commonly found in homes built in the 1970s, it’s essential to understand the key safety considerations for its proper use. If you are purchasing a home with aluminum wiring or have discovered it after moving in, I highly recommend hiring a licensed electrician to thoroughly inspect the wiring for the following:

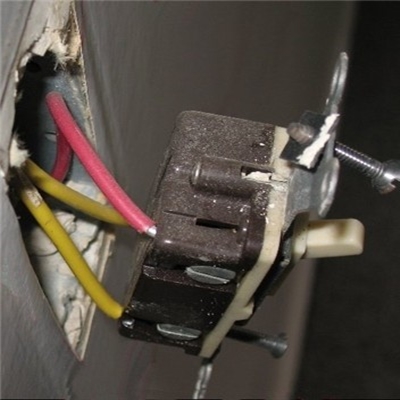

1) Fixtures like outlets and switches that are connected directly to aluminum wiring must be specifically rated for compatibility. Approved devices will be marked with "Al/Cu" or "CO/ALR," with CO/ALR representing the updated and safer standard. Both types are considered safe for use with aluminum wiring. While these fixtures may be more expensive than standard ones, they are crucial for ensuring a safe and reliable electrical system.

2) Wires should be securely connected, wrapping at least three-quarters of the way around the screw in a clockwise direction. This ensures a tight connection, promoting proper conductivity and reducing the risk of overheating. However, repeatedly tightening the screws can exacerbate the issue by damaging the wire or the connection point. During an inspection, it’s best to carefully examine each connection and gently snug it as needed to ensure a secure and stable fit.

{Note: Stranded aluminum wiring is still commonly used for the main service entrance cable at the main panel and should be thoroughly inspected as part of the overall electrical evaluation.}

3) Push-in terminals present a significant hazard when used with aluminum wiring. To enhance safety, any connections utilizing push-in terminals should be promptly upgraded to secure screw connections.

4) There should be no signs of overheating, such as discolored connections, melted insulation, or "baked" fixtures. If any of these issues are found, a licensed electrician should be called to make repairs, and the connection should be upgraded to a safer alternative.

5) Connections between aluminum and copper wires must be handled with special care. Current codes require connectors specifically marked for aluminum-to-copper connections. The National Electrical Code (NEC) mandates that these wires be joined using specialized crimping devices and anti-oxidant grease. The tools and materials required for this process can be expensive, making it impractical to attempt the job yourself unless you can rent the necessary equipment.

{Note that regulations in this area are evolving rapidly. If you plan to make more than one or two connections, it is advisable to consult with a licensed electrical inspector to ensure compliance with the latest codes.}

6) Any non-rated receptacles can be safely connected to aluminum wiring by using a short copper "pigtail" as described in point #5 above.

If, during the inspection of the exposed wiring in the home you're considering purchasing, I find no issues, you can consider the wiring safe. However, if there are signs of electrical problems in multiple areas (which will be noted on page 16 of your home inspection report), I recommend scheduling a full electrical inspection and potentially upgrading all branch wiring throughout the house. If incorrect receptacles are used, they can be replaced with the appropriate type or have pigtails installed by an electrician. Having this work professionally completed by a licensed electrician who will typically charge per receptacle or switch, plus hourly labor.

Here is what my clients have to say about my home inspection services:

Press F5 (on your keyboard) for additional testimonials

Hi Dave,

I just wanted to write a quick thank you for your work inspecting 43 1/2 Bartholomew Street in Peabody yesterday. As a buyer in the process of trying to purchase my first home, it's been difficult to know who to trust. I honestly cannot believe some of the stuff I've run into, so I had to write & let you know that I found you professional, competent, & all around above par. In all of the people I've had to deal with up to this point, you were one of the few that actually took the time to explain things in a way that an inexperienced first time home buyer would understand. I never once felt rushed or talked down to.

Based on your inspection, I've decided not to purchase the home at 43 1/2 Bartholomew Street. I will however, continue to look & will hopefully find a house more suited to my needs in the near future. When that happens I will be calling on your expertise once again. In the meantime, I will certainly recommend you to any of my family & friends that may need a home inspection.

Thanks again,

Lisa G.